Abstract

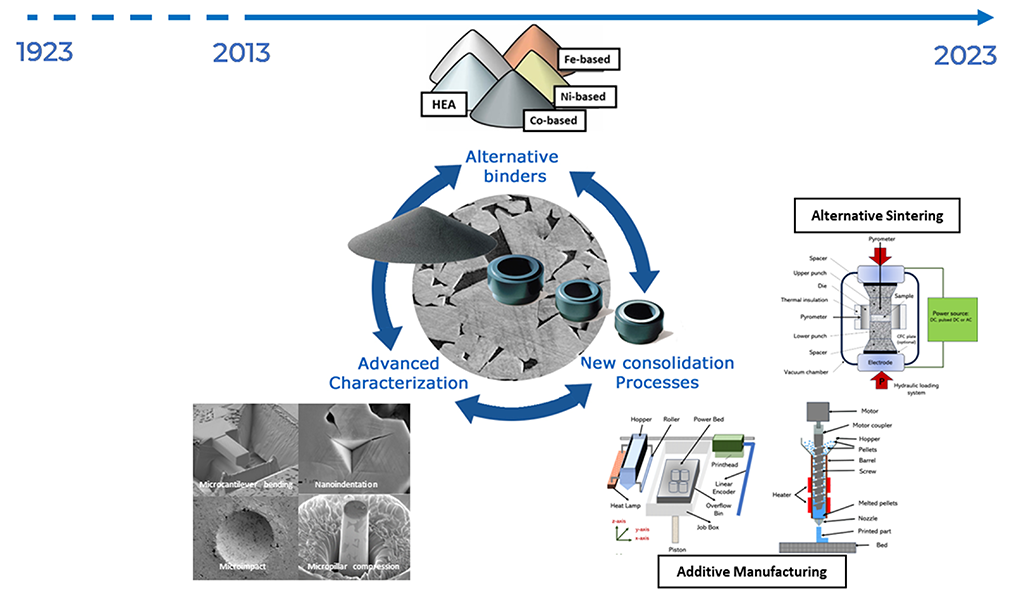

Cemented carbide alloys are well known powder metallurgically processed materials used for a wide range of tooling and components that require a good balance of hardness and fracture toughness, together with wear resistance. After 100 years of the first patent, research and development within this area continues to fulfil more demanding applications and adapt to new requirements. The last decade especially has witnessed important advances. In that sense, Co-free compositions are being studied due to the health issues that its use implies and its criticality in the supply chain. Secondly, the steps towards near-net-shape components by means of additive manufacturing technologies to avoid waste of powder and the technological advance of fast sintering processes are promising. Finally, new microstructural and mechanical characterization methods at micro and nanoscale provide helpful insights for a better understanding of these materials under performance.

References

Altıparmak, S. C.; Yardley, V. A.; Shi, Z.; Lin, J. Extrusion-based additive manufacturing technologies: State of the art and future perspectives. J. Manufact. Proc. 2022, 83, 607–636. https://doi.org/10.1016/j.jmapro.2022.09.032

Beake, B. D. Nano- and Micro-Scale Impact Testing of Hard Coatings: A Review. Coatings. 2022, 12 (6), 793. https://doi.org/10.3390/COATINGS12060793

Berger, C.; Pötschke, J.; Scheithauer, U.; Michaelis, A. Correlation of Different Cemented Carbide Starting Powders with the Resulting Properties of Components Manufactured via Binder Jetting. Metals. 2023, 13, 1848. https://doi.org/10.3390/met13111848

Beste, U.; Hammerström, L.; Engqvist, H.; Rimlinger, S.; Jacobson S. Particle erosion of cemented carbides with low Co content. Wear. 2001, 250 (1–12), 809–817. https://doi.org/10.1016/S0043-1648(01)00735-9

Bonny, K.; De Baets, P.; Quintelier, J.; Vleugels, J.; Jiang, D.; VanderBiest, O.; Lauwers, B.; Liu, W. Surface finishing: Impact on tribological characteristics of WC–Co hardmetals. Tribol. Int. 2010, 43 (1–2), 40–54. https://doi.org/10.1016/j.triboint.2009.04.029

Booklet. ADDITIVE MANUFACTURING TECHNOLOGY A Guide for Designers and Engineers. EPMA, 2019. https://www.epma.com/european-additive-manufacturing-group (accessed 2024-01-01).

Boukantar, A. R.; Djerdjare, B.; Guiberteau, F.; Ortiz, A. L. A Critical Comparison of the Tribocorrosive Performance in Highly-Alkaline Wet Medium of Ultrafine-Grained WC Cemented Carbides with Co, Co+Ni, or Co+Ni+Cr Binders. Int. J. Refract. Metals Hard Mater. 2021, 95, 105452. https://doi.org/10.1016/j.ijrmhm.2020.105452

Bram, M.; Beynet, Y.; Van Der Laan, A.; Neubauer, E.; Guillon, O.; Huber, J.; Trapp, J.; Keszler, M.; Luthardt, B.; Hennicke, J. Introduction to Field-Assisted Sintering Technology/Spark Plasma Sintering (FAST/SPS); 2022.

Carreño-Morelli, E.; Alveen, P.; Moseley, S.; Rodriguez-Arbaizar, M.; Cardoso, K. Three-Dimensional Printing of Hard Materials. Int. J. Refract. Metals Hard Mater. 2020, 87, 105110. https://doi.org/10.1016/j.ijrmhm.2019.105110

Chen, W. H.; Lin, H. T.; Nayak, P. K.; Huang, J. L. Material Properties of Tungsten Carbide-Alumina Composites Fabricated by Spark Plasma Sintering. Ceram. Int. 2014, 40 (9 PART B), 15007–15012. https://doi.org/10.1016/j.ceramint.2014.06.102

Chen, R.; Zheng, S.; Zhou, R.; Wei, B.; Yang, G.; Chen, P.; Cheng, J. Development of Cemented Carbides with CoxFeNiCrCu High-Entropy Alloyed Binder Prepared by Spark Plasma Sintering. Int. J. Refract. Metals Hard Mater. 2022, 103, 105751. https://doi.org/10.1016/J.IJRMHM.2021.105751

Chen, C.; Huang, B.; Liu, Z.; Li, Y.; Zou, D.; Liu, T.; Chang, Y.; Chen, L. Additive Manufacturing of WC-Co Cemented Carbides: Process, Microstructure, and Mechanical Properties. Additive Manufacturing. 2023, 63, 103410. https://doi.org/10.1016/j.addma.2023.103410

Chuvil’deev, V. N.; Blagoveshchenskiy, Y. V.; Nokhrin, A. V.; Boldin, M. S.; Sakharov, N. V.; Isaeva, N. V.; Shotin, S. V.; Belkin, O. A.; Popov, A. A.; Smirnova, E. S.; Lantsev, E. A. Spark Plasma Sintering of Tungsten Carbide Nanopowders Obtained through DC Arc Plasma Synthesis. J. Alloys Compd. 2017, 708, 547–561. https://doi.org/10.1016/j.jallcom.2017.03.035

Chychko, A.; García, J.; Collado Ciprés, V.; Holmström, E.; Blomqvist, A. HV-KIC Property Charts of Cemented Carbides: A Comprehensive Data Collection. Int. J. Refract. Metals Hard Mater. 2022, 103, 105763. https://doi.org/10.1016/j.ijrmhm.2021.105763

Cinca, N.; Beake, B. D.; Harris, A. J.; Tarrés, E. Micro-Scale Impact Testing on Cemented Carbides. Int. J. Refract. Metals Hard Mater. 2019, 84, 105045. https://doi.org/10.1016/J.IJRMHM.2019.105045

Cramer, C. L.; Aguirre, T. G.; Wieber, N. R.; Lowden, R. A.; Trofimov, A. A.; Wang, H.; Yan, J.; Paranthaman, M. P.; Elliott, A. M. Binder Jet Printed WC Infiltrated with Pre-Made Melt of WC and Co. Int. J. Refract. Metals Hard Mater. 2020, 87, 105137. https://doi.org/10.1016/j.ijrmhm.2019.105137

Csanádi, T.; Bľanda, M.; Naughton-Duszová, A.; Chinh, N. Q.; Szommer, P.; Dusza, J. Deformation Characteristics of WC Micropillars. J. Eur. Ceram. Soc. 2014, 34 (15), 4099–4103. https://doi.org/10.1016/J.JEURCERAMSOC.2014.05.045

Csanádi, T.; Bl’Anda, M.; Chinh, N. Q.; Hvizdoš, P.; Dusza, J. Orientation-Dependent Hardness and Nanoindentation-Induced Deformation Mechanisms of WC Crystals. Acta Mater. 2015, 83, 397–407. https://doi.org/10.1016/J.ACTAMAT.2014.09.048

Csanádi, T.; Vojtko, M.; Dusza, J. Deformation and Fracture of WC Grains and Grain Boundaries in a WC-Co Hardmetal during Microcantilever Bending Tests. Int. J. Refract. Metals Hard Mater. 2020, 87, 105163. https://doi.org/10.1016/J.IJRMHM.2019.105163

Davis, J. R. ASM Specialty Handbook: Tool Materials; ASM International, 1995.

Dong, D.; Xiang, X.; Huang, B.; Xiong, H.; Zhang, L.; Shi, K.; Liao, J. Microstructure and Properties of WC-Co/CrMnFeCoNi Composite Cemented Carbides. Vacuum. 2020, 179, 109571. https://doi.org/10.1016/J.VACUUM.2020.109571

Elizalde, M. R.; Ocaña, I.; Alkorta, J.; Sánchez-Moreno, J. M. Mechanical Strength Assessment of Single WC-WC Interfaces Present in WC-Co Hardmetals through Micro-Beam Bending Experiments. Int. J. Refract. Metals Hard Mater. 2018, 72, 39–44. https://doi.org/10.1016/J.IJRMHM.2017.12.009

Elliot, A.; Cramer, C.; Nandwana, P. Binder Jetting and Sintering in Additive Manufacturing; USDOE Office of Energy Efficiency and Renewable Energy (EERE), 2020. https://doi.org/10.31399/asm.hb.v24.a0006569

Enneti, R. K.; Prough, K. C. Wear Properties of Sintered WC-12%Co Processed via Binder Jet 3D Printing (BJ3DP). Int. J. Refract. Metals Hard Mater. 2019, 78, 228–232. https://doi.org/10.1016/j.ijrmhm.2018.10.003

Eriksson, M.; Radwan, M.; Shen, Z. Spark Plasma Sintering of WC, Cemented Carbide and Functional Graded Materials. Int. J. Refract. Metals Hard Mater. 2013, 36, 31–37. https://doi.org/10.1016/j.ijrmhm.2012.03.007

Ettmayer, P.; Kolaska, H.; Ortner, H. M. History of Hardmetals. In Comprehensive Hard Materials Vol. 1-3; Sarin, V.; Mari, D.; Llanes, L.; Nebel, C. E., Eds.; Elsevier, 2014; pp 3–27. https://doi.org/10.1017/CBO9781107415324.004

Exner, H. E. Physical and Chemical Nature of Cemented Carbides. Int. Mat. Rev. 1979, 4, 1149–1173. https://doi.org/10.1179/imtr.1979.24.1.149

Fathipour, Z.; Hadi, M.; Maleki, M.R.; Fernandes, F. Effect of Binder on Oxidation Properties of Tungsten Carbides: A Review by a Conceptual Classification Approach. Ceramics. 2024, 7, 166–191. https://doi.org/10.3390/ceramics7010011

Fayyaz, A.; Muhamad, N.; Sulong, A. B.; Rajabi, J.; Wong, Y. N. Fabrication of Cemented Tungsten Carbide Components by Micro-Powder Injection Moulding. J. Mater. Process Technol. 2014, 214 (7), 1436–1444. https://doi.org/10.1016/j.jmatprotec.2014.02.006

Fayyaz, A.; Muhamad, N.; Sulong, A. B. Microstructure and Physical and Mechanical Properties of Micro Cemented Carbide Injection Moulded Components. Powder Technol. 2018, 326, 151–158. https://doi.org/10.1016/j.powtec.2017.12.011

Furberg, A.; Arvidsson, R.; Molander, S. Environmental Life Cycle Assessment of Cemented Carbide (WC-Co) Production. J. Clean Prod. 2019, 209, 1126–1138. https://doi.org/10.1016/j.jclepro.2018.10.272

Gant, A. J.; Gee, M. G.; May, A. T. The Evaluation of Tribo-Corrosion Synergy for WC-Co Hardmetals in Low Stress Abrasion. Wear. 2004, 256 (5), 500–516. https://doi.org/10.1016/j.wear.2003.04.001

Gant, A. J.; Gee, M. G.; Gohil, D. D.; Jones, H. G.; Orkney, L. P. Use of FIB/SEM to Assess the Tribo-Corrosion of WC/Co Hardmetals in Model Single Point Abrasion Experiments. Tribol. Int. 2013, 68, 56–66. https://doi.org/10.1016/J.TRIBOINT.2012.11.008

García, J.; Collado Ciprés, V.; Blomqvist, A.; Kaplan, B. Cemented Carbide Microstructures: A Review. Int. J. Refract. Metals Hard Mater. 2019, 80, 40–68. https://doi.org/10.1016/j.ijrmhm.2018.12.004

Gee, M. G.; Gant, A.; Roebuck, B. Wear Mechanisms in Abrasion and Erosion of WC / Co and Related Hardmetals. Wear. 2007, 263, 137–148. https://doi.org/10.1016/j.wear.2006.12.046

Gee, M. G.; Nimishakavi, L. Model Single Point Abrasion Experiments on WC/Co Hardmetals. Int. J. Refract. Metals Hard Mater. 2011, 29 (1), 1–9. https://doi.org/10.1016/J.IJRMHM.2010.04.009

Gee, M.; Mingard, K.; Nunn, J.; Roebuck, B.; Gant, A. In Situ Scratch Testing and Abrasion Simulation of WC/Co. Int. J. Refract. Metals Hard Mater. 2017, 62, 192–201. https://doi.org/10.1016/J.IJRMHM.2016.06.004

German, R. M. A-Z of Powder Metallurgy; Elsevier, 2005.

Góez, A.; Coureaux, D.; Ingebrand, A.; Reig, B.; Tarrés, E.; Mestra, A.; Mateo, A.; Jiménez-Piqué, E.; Llanes, L. Contact damage and residual strength in hardmetals, Int. J. Refract. Metals Hard Mater. 2012, 30, 121–127. https://doi.org/10.1016/j.ijrmhm.2011.07.013

Grilli, M. L.; Bellezze, T.; Gamsjäger, E.; Rinaldi, A.; Novak, P.; Balos, S.; Piticescu, R. R.; Ruello, M. L. Solutions for Critical Raw Materials under Extreme Conditions: A Review. Materials. 2017, 10, 285. https://doi.org/10.3390/ma10030285

Grohol, M; Veeh, C. Study on the Critical Raw Materials for the EU 2023; European Comission, 2023. https://op.europa.eu/en/publication-detail/-/publication/57318397-fdd4-11ed-a05c-01aa75ed71a1 (accessed 2024-01-01).

Guan, Z.; Li, N.; Zhang, W.; Wang, J.; Wang, C.; Shen, Q.; Xu, Z.; Peng, J.; Du, Y. A Multiple Loops Machine Learning Framework to Predict the Properties of WC–Co Based Cemented Carbides. Int. J. Refract. Metals Hard Mater. 2022, 104, 105798. https://doi.org/10.1016/j.ijrmhm.2022.105798

Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-Assisted Sintering Technology/Spark Plasma Sintering: Mechanisms, Materials, and Technology Developments. Adv. Eng. Mater. 2014, 16 (7), 830–849. https://doi.org/10.1002/adem.201300409

Guillon, O.; Rheinheimer, W.; Bram, M. A Perspective on Emerging and Future Sintering Technologies of Ceramic Materials. Adv. Eng. Mater. 2023, 25, 2201870. https://doi.org/10.1002/adem.202201870

Guo, B.; Zhang, L.; Cao, L.; Zhang, T.; Jiang, F.; Yan, L. The Correction of Temperature-Dependent Vickers Hardness of Cemented Carbide Base on the Developed High-Temperature Hardness Tester. J. Mater. Process Technol. 2018, 255, 426–433. https://doi.org/10.1016/J.JMATPROTEC.2017.12.041

Gupta, A. K.; Taulik, M. Effect of Process Variables on Performances Measured in Filament and Pellet Based Extrusion Processes. Materials Today. 2021, 47 (15) 5177–5184. https://doi.org/10.1016/j.matpr.2021.05.508

Gurland, J. New scientific approaches to development of tool materials. Int. Mater. Rev. 1988, 33 (1), 151–166. https://doi.org/10.1179/imr.1988.33.1.151

Heng, S. Y.; Raza, M. R.; Muhamad, N.; Sulong, A. B.; Fayyaz, A. Micro-Powder Injection Molding (ΜPIM) of Tungsten Carbide. Int. J. Refract. Metals Hard Mater. 2014, 45, 189–195. https://doi.org/10.1016/j.ijrmhm.2014.04.012

Hering, B.; Gestrich, T.; Steinborn, C.; Vornberger, A.; Pötschke, J. Influence of Alternative Hard and Binder Phase Compositions in Hardmetals on Thermophysical and Mechanical Properties. Metals. 2023, 13, 1803. https://doi.org/10.3390/met13111803

Hu, D.; Liu, Y.; Chen, H.; Wang, M. Microstructure and Wear Resistance of Ni-Based Tungsten Carbide Coating by Laser Cladding on Tunnel Boring Machine Cutter Ring. Surf. Coat. Technol. 2020, 404, 126432. https://doi.org/10.1016/j.surfcoat.2020.126432

Hyperion Materials & Technologies. All about cemented carbide. http://www.allaboutcementedcarbide.com/ (accessed 2019-08-22).

Javaid, M.; Haleem, A.; Singh, R.; Suman, R.; Rab, S. Role of additive manufacturing applications towards environmental sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4 (4), 312. https://doi.org/10.1016/j.aiepr.2021.07.005

Jiménez-Piqué, E.; Turon-Vinas, M.; Chen, H.; Trifonov, T.; Fair, J.; Tarrés, E.; Llanes, L. Focused ion beam tomography of WC-Co cemented carbides, Int. J. Refract. Metals Hard Mater. 2017, 67, 9–17. https://doi.org/10.1016/j.ijrmhm.2017.04.007

Kim, H.; Kim, J. I.; Ryu, S. S.; Jeong, H. Cast WC-Co Alloy-Based Tool Manufacturing Using a Polymeric Mold Prepared via Digital Light Processing 3D Printing. Mater. Lett. 2022, 306. https://doi.org/10.1016/j.matlet.2021.130979

Klünsner, T.; Wurster, S.; Supancic, P.; Ebner, R.; Jenko, M.; Glätzle, J.; Püschel, A.; Pippan, R. Effect of specimen size on the tensile strength of WC–Co hard metal. Acta Mater. 2011, 59, 4244–4252. https://doi.org/10.1016/j.actamat.2011.03.049

Konyashin, I.; Lachmann, F.; Ries, B.; Mazilkin, A.; Straumal, B.; Kübel, C.; Llanes, L.; Baretzky, B. Strengthening Zones in the Co Matrix of WC–Co Cemented Carbides. Scr Mater 2014, 83, 17–20. https://doi.org/10.1016/J.SCRIPTAMAT.2014.03.026

Konyashin, I.; Ries, B.; Hlawatschek, D.; Zhuk, Y.; Mazilkin, A.; Straumal, B.; Dorn, F.; Park, D. Wear-Resistance and Hardness: Are They Directly Related for Nanostructured Hard Materials? Int. J. Refract. Metals Hard Mater. 2015, 49 (1), 203–211. https://doi.org/10.1016/J.IJRMHM.2014.06.017

Konyashin, I. Approaching the 100th Anniversary of the Hardmetal Invention: From First WC-Co Samples towards Modern Advanced Hardmetal Grades. Int. J. Refract. Metals Hard Mater. 2023, 111, 106113. https://doi.org/10.1016/J.IJRMHM.2023.106113

Lavigne, O.; Cinca, N.; Ther, O.; Tarrés, E. Effect of Binder Nature and Content on the Cavitation Erosion Resistance of Cemented Carbides. Int. J. Refract. Metals Hard Mater. 2022, 109, 105978. https://doi.org/10.1016/j.ijrmhm.2022.105978

Lay, S.; Missiaen, J. M. Microstructure and Morphology of Hardmetals. In Comprehensive Hard Materials; Sarin, V. K., Mari, D., Llanes, L., Nebel, C. E., Eds.; Elsevier, 2014; pp 91–117.

Lebedev, A.; Alves, N.; Balbino, N.; Otoni Corrêa, E.; Roque Huanca, D.; Amaury De Freitas Matos, F.; De Carvalho Valeriano, L. Comparative Study of Corrosion Behaviors of WC-NiMo and WC-Co Cemented Carbides. Materials. 2023, 16 (12), 4480. https://doi.org/10.3390/MA16124480

Lengauer, W.; Kukla, C.; Kitzmantel, M.; Duretek, I.; Schwarz, V.; Neubauer, E.; Lieberwirth, C.; Morrison, V. Preparation and properties of extrusion-based 3D-printed hardmetal and cermet parts. In: Proceedings of the Euro PM2018 Congress & Exhibition Euro PM2018 Proceedings, Bilbao Exhibition Centre (BEC), Bilbao, Spain. 2018. p. 14-18.

Long, J.; Zhang, W.; Wang, Y.; Du, Y.; Zhang, Z.; Lu, B.; Cheng, K.; Peng, Y. A New Type of WC–Co–Ni–Al Cemented Carbide: Grain Size and Morphology of Γ′-Strengthened Composite Binder Phase. Scr. Mater. 2017, 126, 33–36. https://doi.org/10.1016/j.scriptamat.2016.08.007

Luo, W.; Liu, Y.; Liu, X.; Zhou, Z. Oxidation behavior of ultrafine WC-based cemented carbides with AlxCoCrCuFeNi high-entropy alloy binders. Ceram. Intern. 2021, 47, 8498–8509. https://doi.org/10.3390/met13010171

Mahani, F.; Liu, C.; Sousa Machado, P. V.; Lin, L. L.; Wen, X.; Jiménez-Piqué, E.; Llanes, L.; Contact damage induced by means of conical indentation in hardmetals: Microstructural effects on residual strength. Int. J. Refract. Metals Hard Mater. 2024, 118, 106446, https://doi.org/10.1016/j.ijrmhm.2023.106446

Maier, K.; Klünsner, T.; Krobath, M.; Pichler, P.; Marsoner, S.; Ecker, W.; Czettl, C.; Schäfer, J.; Ebner, R. Creep Behaviour of WC-12 Wt% Co Hardmetals with Different WC Grain Sizes Tested in Uniaxial Tensile and Compression Step-Loading Tests at 700 °C and 800 °C. Int. J. Refract. Metals Hard Mater. 2021, 100, 105633. https://doi.org/10.1016/J.IJRMHM.2021.105633

Mingard, K. P.; Roebuck, B.; Marshall, J.; Sweetman, G. Some Aspects of the Structure of Cobalt and Nickel Binder Phases in Hardmetals. Acta Mater. 2011, 59 (6), 2277–2290. https://doi.org/10.1016/J.ACTAMAT.2010.12.004

Miyanaji, H.; Orth, M.; Akbar, J. M.; Yang, L. Process Development for Green Part Printing Using Binder Jetting Additive Manufacturing. Front. Mech. Eng. 2018, 13, 504–512. https://doi.org/10.1007/s11465-018-0508-8

Mostafaei, A.; Neelapu, S. H. V. R.; Kisailus, C.; Nath, L. M.; Jacobs, T. D. B.; Chmielus, M. Characterizing surface finish and fatigue behavior in binder-jet 3D-printed nickel-based superalloy 625. Additive Manufacturing. 2018, 24, 200–209. https://doi.org/10.1016/j.addma.2018.09.012

Mueller-Grunz, A.; Alveen, P.; Rassbach, S.; Useldinger, R.; Moseley, S. The Manufacture and Characterization of WC-(Al)CoCrCuFeNi Cemented Carbides with Nominally High Entropy Alloy Binders. Int. J. Refract. Metals Hard Mater. 2019, 84, 105032. https://doi.org/10.1016/j.ijrmhm.2019.105032

Naughton-Duszová, A.; Csanádi, T.; Sedlák, R.; Hvizdoš, P.; Dusza, J. Small-Scale Mechanical Testing of Cemented Carbides from the Micro-to the Nano-Level: A Review. Metals. 2019, 9 (5), 502. https://doi.org/10.3390/met9050502

Naughton-Duszová, A.; Halgaš, R.; Bľanda, M.; Hvizdoš, P.; Lofaj, F.; Dusza, J.; Morgiel, J. Nanoindentation of WC–Co Hardmetals. J. Eur. Ceram. Soc. 2013, 33 (12), 2227–2232. https://doi.org/10.1016/J.JEURCERAMSOC.2012.12.018

Nicolás-Morillas, M.; Besharatloo, H.; Alvaredo, P.; Roa, J. J.; Llanes, L.; Gordo, E. Design of alternative binders for hard materials. Int. J. Refract. Metals Hard Mater. 2020, 87, 105089. https://doi.org/10.1016/j.ijrmhm.2019.105089

Nicolás-Morillas, M.; Llanes, L.; Gordo, E. High-temperature wettability in hard materials: Comparison of systems with different binder/carbide phases and evaluation of C addition. Int. J. Refract. Metals Hard Mater. 2023, 111, 106081. https://doi.org/10.1016/j.ijrmhm.2022.106081

Nicolás-Morillas, M.; Besharatloo, H.; Cabezas, L.; la Mata, M.; Sales, D. L.; Pereira, L.; Müller-Grunz, A.; Bertalan, C.; Useldinger, R.; Llanes, L.; Gordo, E.; Processing of WC with Fe-based alternative binders: Adjustment of C content and effect of Cr addition. Int. J. Refract. Metals Hard Mater. 2024, 118, 106444. https://doi.org/10.1016/j.ijrmhm.2023.106444

Olsson, M.; Cinca, N. Mechanisms controlling friction and material transfer in sliding contacts between cemented carbide and aluminum during metal forming. Int. J. Refract. Metals Hard Mater. 2024, 1184, 106481. https://doi.org/10.1016/j.ijrmhm.2023.106481

Ortiz-Membrado, L.; Cuadrado, N.; Casellas, D.; Roa, J. J.; Llanes, L.; Jiménez-Piqué, E. Measuring the Fracture Toughness of Single WC Grains of Cemented Carbides by Means of Microcantilever Bending and Micropillar Splitting. Int. J. Refract. Metals Hard Mater. 2021, 98, 105529. https://doi.org/10.1016/j.ijrmhm.2021.105529

Ortner, H. M.; Ettmayer, P.; Kolaska, H. The History of the Technological Progress of Hardmetals. Int. J. Refract. Metals Hard Mater. 2014, 44, 148–159. https://doi.org/10.1016/j.ijrmhm.2013.07.014

Padmakumar, M. Additive Manufacturing of Tungsten Carbide Hardmetal Parts by Selective Laser Melting (SLM), Selective Laser Sintering (SLS) and Binder Jet 3D Printing (BJ3DP) Techniques. Lasers in Manufacturing and Materials Processing. 2020, 7, 338–371. https://doi.org/10.1007/s40516-020-00124-0

Perez Delgado, Y.; Bonny, K.; Baets, P.; Neis, P. D.; Rodriguez Fereira, V.; Malek, O.; Vleugels, J.; Lauwers, B. Dry sliding friction and wear response of WC-Co hardmetal pairs in linearly reciprocating and rotating contact. Sustainable Construction and Design. 2011, 12–18.

Pötschke, J.; Berger, C.; Richter, H. J.; Scheithauer, U.; Weingarten, S. Additive manufacturing of hardmetals. In Proceedings of European Powder Metallurgy, 2017. https://publica-rest.fraunhofer.de/server/api/core/bitstreams/a474fa1b-4efe-4390-8560-5fd14b276368/content (accessed 2024-01-01).

Prakash, L. Developments in Tungsten Carbide-Cobalt Cemented Carbides; Inovar communications, 2008.

Prakash, L. Fundamentals and General Applications of Hardmetals. In Comprehensive Hard Materials Vol. 1-3; Sarin, V.; Mari, D.; Llanes, L.; Nebel, C. E., Eds.; Elsevier, 2014; pp 29–90.

Raihanuzzaman, R. M.; Xie, Z.; Hong, S. J.; Ghomashchi, R. Powder Refinement, Consolidation and Mechanical Properties of Cemented Carbides - An Overview. Powder Technol. 2014, 261, 1–13. https://doi.org/10.1016/j.powtec.2014.04.024

Roa, J. J.; Jimenez-Pique, E.; Verge, C.; Tarragó, J. M.; Mateo, A.; Fair, J.; Llanes, L. Intrinsic Hardness of Constitutive Phases in WC-Co Composites: Nanoindentation Testing, Statistical Analysis, WC Crystal Orientation Effects and Flow Stress for the Constrained Metallic Binder. J. Eur. Ceram. Soc. 2015, 35 (13), 3419–3425. https://doi.org/10.1016/j.jeurceramsoc.2015.04.021

Roa, J. J.; Jiménez-Piqué, E.; Tarragó, J. M.; Sandoval Ravotti, D. A.; Mateo, A.; Fair, J.; Llanes, L. Hall-Petch Strengthening of the Constrained Metallic Binder in WC–Co Cemented Carbides: Experimental Assessment by Means of Massive Nanoindentation and Statistical Analysis. Materials Science and Engineering: A. 2016, 676, 487–491. https://doi.org/10.1016/J.MSEA.2016.09.020

Roebuck, B.; Almond, E. A. Deformation and Fracture Processes and the Physical Metallurgy of WC–Co Hardmetals. International Materials Reviews. 1988, 33 (2), 90–110. https://doi.org/10.1179/095066088790324094

Roebuck, B.; Klose, P.; Mingard, K. P. Hardness of Hexagonal Tungsten Carbide Crystals as a Function of Orientation. Acta Mater. 2012, 60 (17), 6131–6143. https://doi.org/10.1016/J.ACTAMAT.2012.07.056

Roulon, Z.; Missiaen, J. M.; Lay, S. Carbide Grain Growth in Cemented Carbides Sintered with Alternative Binders. Int. J. Refract. Metals Hard Mater. 2020, 86, 105088. https://doi.org/10.1016/j.ijrmhm.2019.105088

Sandoval Ravotti, D. A.; Rinaldi, A.; Tarragó, J. M.; Roa, J. J.; Fair, J.; Llanes, L. Scale Effect in Mechanical Characterization of WC-Co Composites. Int. J. Refract. Metals Hard Mater. 2018, 72, 157–162. https://doi.org/10.1016/J.IJRMHM.2017.12.029

Sandoval Ravotti, D. A. Small-Scale Testing of Micromechanical Response of Cemented Carbides. Thesis (Doctorate), Universitat Politècnica de Catalunya, Barcelona, 2019.

Sandoval Ravotti, D. A.; Roa, J. J.; Ther, O.; Tarrés, E.; Llanes, L. Micromechanical Properties of WC-(W,Ti,Ta,Nb)C-Co Composites. J. Alloys. Compd. 2019, 777, 593–601. https://doi.org/10.1016/J.JALLCOM.2018.11.001

Sandvik. Understanding cemented carbide. https://pt.scribd.com/document/375993631/SANDVIK-Understanding-cemented-carbide-pdf (accessed 2024-01-01).

Scheithauer, U.; Pötschke, J.; Weingarten, S.; Schwarzer, E.; Vornberger, A.; Moritz, T.; Michaelis, A. Droplet-Based Additive Manufacturing of Hard Metal Components by Thermoplastics 3D Printing. J. Ceram. Sci. Tech. 2017, 8 (1), 155–160. https://doi.org/10.4416/JCST2016-00104

Shatov, A. V.; Ponomarev, S. S.; Firstov, S. A. Hardness and Deformation of Hardmetals at Room Temperature. In Comprehensive Hard Materials Vol. 1-3; Sarin, V.; Mari, D.; Llanes, L.; Nebel, C. E., Eds.; Elsevier, 2014a; pp 267–299. https://doi.org/10.1016/B978-0-08-096527-7.00009-X

Shatov, A. V.; Ponomarev, S. S.; Firstov, S. A. Fracture and strength of hardmetals at room temperature. In Comprehensive Hard Materials Vol. 1-3; Sarin, V.; Mari, D.; Llanes, L.; Nebel, C. E., Eds.; Elsevier, 2014b; pp 301–343. https://doi.org/10.1016/B978-0-08-096527-7.00010-6

Sheikh, S.; M'Saoubi, R.; Flasar, P.; Schwind, M.; Persson, T.; Yang, J.; Llanes, L. Fracture toughness of cemented carbides: Testing method and microstructural effects. Int. J. Refract. Metals Hard Mater. 2015, 49, 153–160. https://doi.org/10.1016/j.ijrmhm.2014.08.018

Sribalaji, M.; Mukherjee, B.; Islam, A.; Kumar Keshri, A. Microstructural and Mechanical Behavior of Spark Plasma Sintered Titanium Carbide with Hybrid Reinforcement of Tungsten Carbide and Carbon Nanotubes. Materials Science and Engineering: A. 2017, 702, 10–21. https://doi.org/10.1016/j.msea.2017.06.108

Steinlechner, R.; Oro Calderon, R.; Koch, T.; Linhardt, P.; Schubert, W. D. A Study on WC-Ni Cemented Carbides: Constitution, Alloy Compositions and Properties, Including Corrosion Behaviour. Int. J. Refract. Metals Hard Mater. 2022, 103, 105750. https://doi.org/10.1016/j.ijrmhm.2021.105750

Straumal, B.; Konyashin, I. WC-Based Cemented Carbides with High Entropy Alloyed Binders: A Review. Metals 2023, 13, 171. https://doi.org/10.3390/met13010171

Suzuki, A.; Inui, H.; Pollock, T. M. L12-Strengthened Cobalt-Base Superalloys. Annu. Rev. Mater. Res. 2015, 45, 345–368. https://doi.org/10.1146/ANNUREV-MATSCI-070214-021043

Tang, W.; Zhang, L.; Zhu, J. fei; Chen, Y.; Tian, W.; Liu, T. Effect of Direct Current Patterns on Densification and Mechanical Properties of Binderless Tungsten Carbides Fabricated by the Spark Plasma Sintering System. Int. J. Refract. Metals Hard Mater. 2017, 64, 90–97. https://doi.org/10.1016/j.ijrmhm.2017.01.010

Tang, T.; Xiao, X.; Xu, K.; Lou, M.; Hu, X.; Li, S.; Zhang, W.; Fan, Z.; Chang, K. Corrosion-Resistant WC-Co Based Cemented Carbides: Computational Design and Experimental Verification. Int. J. Refract. Metals Hard Mater. 2023, 110, 106044. https://doi.org/10.1016/J.IJRMHM.2022.106044

Tarragó, J. M.; Jiménez-Piqué, E.; Schneider, L.; Casellas, D.; Torres, Y.; Llanes, L. FIB/FESEM Experimental and Analytical Assessment of R-Curve Behavior of WC-Co Cemented Carbides. Materials Science and Engineering: A. 2015, 645, 142–149. https://doi.org/10.1016/j.msea.2015.07.090

Trueba, M.; Aramburu, A.; Rodríguez, N.; Iparraguirre, I.; Elizalde, M. R.; Ocaña, I.; Sánchez, J. M.; Martínez-Esnaola, J. M. “In-Situ” Mechanical Characterisation of WC–Co Hardmetals Using Microbeam Testing. Int. J. Refract. Metals Hard Mater. 2014, 43, 236–240. https://doi.org/10.1016/J.IJRMHM.2013.12.005

Upadhyaya, G. S. Nature and Properties of Refractory Carbides; Nova Science Publishers, 1996.

Upadhyaya, G. S. Cemented Tungsten Carbides: Production, Properties and Testing; Noyes Publications, 1998.

Upadhyaya, G. S. Materials Science of Cemented Carbides—an Overview. Mater. Des. 2001, 22 (6), 483–489.

Wachowicz, J.; Kruzel, R.; Bałaga, Z.; Ostrowska, A.; Dembiczak, T. Application of U-FAST Technology in Sintering of Submicron WC-Co Carbides. Materials. 2023, 16 (6), 2450.

Walbrühl, M.; Linder, D.; Ågren, J.; Borgenstam, A. Alternative Ni-Based Cemented Carbide Binder – Hardness Characterization by Nano-Indentation and Focused Ion Beam. Int. J. Refract. Metals Hard Mater. 2018, 73, 204–209. https://doi.org/10.1016/j.ijrmhm.2018.02.017

Wang, J.; Zuo, D.; Zhu, L.; Li, W.; Tu, Z.; Dai, S. Effects and Influence of Y2O3 Addition on the Microstructure and Mechanical Properties of Binderless Tungsten Carbide Fabricated by Spark Plasma Sintering. Int. J. Refract. Metals Hard Mater. 2018, 71, 167–174. https://doi.org/10.1016/j.ijrmhm.2017.11.016

Warren, R. Solid-Liquid Interfacial Energies in Binary and Pseudo-Binary Systems. J. Mater. Sci. 1980, 15 (10), 2489–2496. https://doi.org/10.1007/BF00550752/METRICS

Wolfe, T. A.; Shah, R. M.; Prough, K. C.; Trasorras, J. L. Binder Jetting 3D Printed Cemented Carbide: Mechanical and Wear Properties of Medium and Coarse Grades. Int. J. Refract. Metals Hard Mater. 2023a, 113. https://doi.org/10.1016/j.ijrmhm.2023.106197

Wolfe, T.; Shah, R.; Prough, K.; Trasorras, J. L. Coarse Cemented Carbide Produced via Binder Jetting 3D Printing. Int. J. Refract. Metals Hard Mater. 2023b, 110, 106016. https://doi.org/10.1016/j.ijrmhm.2022.106016

Xu, Z. H.; Ågren, J. A Modified Hardness Model for WC–Co Cemented Carbides. Materials Science and Engineering: A. 2004, 386(1–2), 262–268. https://doi.org/10.1016/J.MSEA.2004.07.061

Xu, H.; Huang, H. Microstructure Evolution and Mechanical Properties of Thermally Sprayed Coating Modified by Laser Remelting and Injection with Tungsten Carbide. Ceram. Int. 2022a, 48 (16), 22854–22868. https://doi.org/10.1016/j.ceramint.2022.04.189

Xu, H.; Huang, H. Plasma Remelting and Injection Method for Fabricating Metal Matrix Composite Coatings Reinforced with Tungsten Carbide. Ceram. Int. 2022b, 48 (2), 2645–2659. https://doi.org/10.1016/j.ceramint.2021.10.048

Yang, Y.; Zhang, C.; Wang, D.; Nie, L.; Wellmann, D.; Tian, Y. Additive Manufacturing of WC-Co Hardmetals: A Review. Int. J. Adv. Manuf. Tech. 2020, 108 (5–6), 1653–1673. https://doi.org/10.1007/s00170-020-05389-5

Zak Fang, Z.; Koopman. M. C. Cemented Tungsten Carbide Hardmetal-An Introduction. In Comprehensive Hard Materials; Sarin, V. K., Mari, D., Llanes, L., Nebel, C. E., Eds.; Elsevier, 2014; pp 123-137. https://doi.org/10.1016/B978-0-08-096527-7.00004-0

Zhao, Z.; Liu, F.; Zhao, M.; Zhong, L.; Xu, Y.; Li, J. A New Strategy to Efficiently Fabricate Tungsten Carbide Coating on Tungsten: Two-Step Interstitial Carburization. Surf. Coat. Technol. 2020, 389, 125579. https://doi.org/10.1016/j.surfcoat.2020.125579

Zheng, Y. F.; Fargas, G.; Besharatloo, H.; Serra, M.; Roa, J. J.; Armelin, E.; Lavigne, O.; Llanes, L.; Assessment of corrosion-induced changes on the mechanical integrity of cemented carbides at small length scales. Int. J. Refract. Metals Hard Mater. 2019, 84, 105033, https://doi.org/10.1016/j.ijrmhm.2019.105033

Zheng, Y.F.; Fargas, G.; Lavigne, O.; Serra, M.; Coureaux, D.; Zhang, P.P.; Yao, Z.H.; Zhang, Q.L.; Yao, J.H.; Llanes, L. Contact fatigue of WC-6%wtCo cemented carbides: Influence of corrosion-induced changes on emergence and evolution of damage, Ceram. Int. 2022a, 48, 5766-5774. https://doi.org/10.1016/j.ceramint.2021.11.124

Zheng, Y.; Fargas, G.; Armelin, E.; Lavigne, O.; Zhang, Q.; Yao, J.; Llanes, L. Influence of Corrosion-Induced Damage on Mechanical Integrity and Load-Bearing Capability of Cemented Carbides. Metals. 2022b, 12, 2104. https://doi.org/10.3390/met12122104

Zhou, P. F.; Xiao, D. H.; Yuan, T. C. Comparison between Ultrafine-Grained WC–Co and WC–HEA-Cemented Carbides. Powder Metallurgy. 2016, 60 (1), 1–6. https://doi.org/10.1080/00325899.2016.1260903

Zhou, P. L.; Xiao, D. H.; Zhou, P. F.; Yuan, T. C. Microstructure and Properties of Ultrafine Grained AlCrFeCoNi/WC Cemented Carbides. Ceram. Int. 2018, 44 (14), 17160–17166. https://doi.org/10.1016/J.CERAMINT.2018.06.171

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright (c) 2024 Eclética Química