Abstract

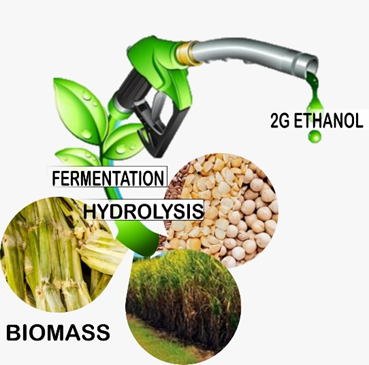

The use of biological agents for the large-scale production of biofuels has stood out as successful processes for the advancement of science in the world. The growing exploitation of biomass in the agricultural sector and the emergence of new energy sources generated from food industry waste have become attractive and viable due to the potential and variety of possibilities for using different sources of biomass. The present review was carried out through careful bibliographical research in the literature and in scientific journals for the current discussion of concepts, production methodologies and challenges for the energy sector considering second-generation ethanol (2G ethanol). Several 2G ethanol production methodologies have been implemented as a potential low-cost alternative energy production that follows the principles of Green Chemistry.

References

Agbor, V. B.; Cicek, N.; Sparling, R.; Berlin, A.; Levin, D. B. Biomass pretreatment: fundamentals toward application. Biotechnol. Adv. 2011, 29 (6), 675–685. https://doi.org/10.1016/j.biotechadv.2011.05.005

Agência Brasil. Brasil deve produzir 31,6 bilhões de litros de etanol este ano. Agência Brasil, 2019. https://agenciabrasil.ebc.com.br/economia/noticia/2019-08/brasil-deve-produzir-316-bilhoes-de-litros-de-etanol-este-ano (accessed 2020-08-20).

Allinger, N. L.; Cava, M. P.; Jongh, D. C.; Johnson, C. R.; Lebel, N. A.; Stevens, C. L. Química orgânica, 2nd. Livros Técnicos e Científicos; 1976.

Antunes, D. P. C.; Viana, V. L.; Santos, M. C. S.; Soares, E. L. S.; Barbosa, K. L.; Moura, K. L.; Vieira, R. C.; Almeida, R. M. R. G. Produção de bioetanol de segunda geração a partir do hidrolisado do albedo da laranja como fonte de biomassa lignocelulósica. Blucher Chem. Eng. Proc. 2015, 1 (2), 305–312. https://doi.org/10.5151/chemeng-cobeq2014-0206-26537-171359

Asakawa, A.; Kohara, M.; Sasaki, C.; Asada, C.; Nakamura, Y. Comparison of choline acetate ionic liquid pretreatment with various pretreatments for enhancing the enzymatic saccharification of sugarcane bagasse. Ind. Crops Prod. 2015, 71, 147–152. https://doi.org/10.1016/j.indcrop.2015.03.073

Assumpção, S. M. N.; Pontes, L. A. M.; Carvalho L. S.; Campos, L. M. A.; Andrade, J. C. F.; Silva, E. G. Pré-tratamento combinado H2SO4/H2O2/NaOH para obtenção das frações lignocelulósicas do bagaço da cana-de-açúcar. Rev. Virt. Quim. 2016, 8 (3), 803–822. https://doi.org/10.5935/1984-6835.20160059

Beig, B.; Riaz, M.; Naqvi, S. R.; Hassan, M.; Zheng, Z.; Karimi, K.; Pugazhendhi, A.; Atabani, A. E.; Chi, N. T. L. Current challenges and innovative developments in pretreatment of lignocellulosic residues for biofuel production: A review. Fuel. 2021, 287, 119670. https://doi.org/10.1016/j.fuel.2020.119670

Bender, T. A., Dabrowski, J. A.; Gagné, M. R. Homogeneous catalysis for the production of low-volume, high-value chemicals from biomass. Nat. Rev. Chem. 2018, 2 (5), 35–46. https://doi.org/10.1038/s41570-018-0005-y

Boechat, C. A.; Pitta, F. T.; Toledo, C. A. National State territoriality pattern and capital autonomization in Brazilian sugar-energy agribusiness: from the Ometto family’s heritage to professionalization and financialization of Cosan. Revista NERA. 2022, 25 (63), 67–95.

Cabral, M. M. S.; Abud, A. K. S.; Silva, C. E. F.; Almeida, R. M. R. G. Bioethanol production from coconut husk fiber. Cienc. Rural. 2016, 46 (10), 1872–1877. https://doi.org/10.1590/0103-8478cr20151331

Carrillo, F.; Lis, M. J.; Colom, X.; López-Mesas, M.; Valldeperas, J. Effect of alkali pretreatment on cellulase hydrolysis of wheat straw: Kinetic study. Process Biochem. 2005, 40 (10), 3360–3364. https://doi.org/10.1016/j.procbio.2005.03.003

Cui, S.; Xie, Y.; Wei, X.; Zhang, K.; Chen, X. Exploration of the chemical linkages between lignin and cellulose in poplar wood with 13C and Deuterium dual isotope tracer. Ind. Crops Prod. 2022, 187 (Part. B), 115452. https://doi.org/10.1016/j.indcrop.2022.115452

Cunha, F. M.; Bacchin, A. L. G.; Horta, A. C. L.; Zangirolami, T. C.; Badino, A. C.; Farinas, C. S. Indirect method for quantification of cellular biomass in solids containing medium used as pre-culture for cellulase production. Biotechnol Bioproc E. 2012, 17 (1), 100–108. https://doi.org/10.1007/s12257-011-0405-z

Cypriano, D. Z.; Silva, L. L.; Mariño, M. A.; Tasic, L. A Biomassa da laranja e seus subprodutos. Rev. Virtual Quim. 2017, 9 (1), 176–191. https://doi.org/10.21577/1984-6835.20170014

Elias, A. M.; Longati, A. A.; Giordano, R. C.; Furlan, F. F. Retro-techno-economic-environmental analysis improves the operation efficiency of 1G-2G bioethanol and bioelectricity facilities. Appl. Energy. 2021, 282 (Part. A), 116133. https://doi.org/10.1016/j.apenergy.2020.116133

Florencio, C.; Badino, A. C.; Farinas, C. S. Soybean protein as a cost-effective lignin-blocking additive for the saccharification of sugarcane bagasse. Bioresour. Technol. 2016, 221, 172–180. https://doi.org/10.1016/j.biortech.2016.09.039

Fu, D.; Mazza, G. Aqueous ionic liquid pretreatment of straw. Bioresour. Technol. 2011, 102 (13), 7008–7011. https://doi.org/10.1016/j.biortech.2011.04.049

Grasel, F. S.; Stiehl, A. C. R.; Bernardi, L. P.; Herpich, T. L.; Behrens, M. C.; Andrade, J. B.; Schultz, J.; Mangrich, A. S. Inovação em biorrefinarias I. Produção de etanol de segunda geração a partir de capim-elefante (Pennisetum purpureum) e bagaço de cana-de-açúcar (Saccharum officinarum). Rev. Virtual Quim. 2017, 9 (1), 4–14. https://doi.org/10.21577/1984-6835.20170003

Harmsen, P. F. H.; Huijgen, W. J. J.; Bermudez López, L. M.; Bakker, R. R. C. Literature Review of Physical and Chemical Pretreatment processes for Lignocellulosic Biomass. Report of the BioSynergy project, 2010.

Hasner, C.; Santos, D. A.; Lima, A. A. Etanol no Brasil: Evolução do patenteamento de tecnologias de fermentação para a produção de etanol combustível de cana-de-açúcar no período de 2007 a 2014. Cad. Prospec. 2015, 8 (1), 133–141. https://doi.org/10.9771/S.CPROSP.2015.001.015

Herrera-Ruales, F. C.; Arias-Zabala, M. Bioethanol production by fermentation of hemicellulosic hydrolysates of African palm residues using an adapted strain of Scheffersomyces stipitis. Dyna. 2014, 81 (185), 204–210. https://doi.org/10.15446/dyna.v81n185.38552

Huang, C.; Li, R.; Tang, W.; Zheng, Y.; Meng, X. Improve Enzymatic Hydrolysis of Lignocellulosic Biomass by Modifying Lignin Structure via Sulfite Pretreatment and Using Lignin Blockers. Fermentation. 2022, 8 (10), 558. https://doi.org/10.3390/fermentation8100558

Ilanidis, D.; Wu, G.; Stagge, S.; Martín, C.; Jönsson, L. J. Effects of redox environment on hydrothermal pretreatment of lignocellulosic biomass under acidic conditions. Bioresour. Technol. 2021, 319, 124211. https://doi.org/10.1016/j.biortech.2020.124211

Jönsson, L. J.; Martín, C. Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. https://doi.org/10.1016/j.biortech.2015.10.009

Karatzos, S. K.; Edye, L. A.; Doherty, W. O. S. Sugarcane bagasse pretreatment using three imidazolium-based ionic liquids; mass balances and enzyme kinetics. Biotechnol. Biofuels. 2012, 5, 62. https://doi.org/10.1186/1754-6834-5-62

Kowalski, R. L.; Schneider, V. S.; Moretto, J.; Gomes, L. F. S. Produção de etanol de segunda geração a partir de caroço de abacate (Persea americana Mill.). Revista Brasileira de Energias Renováveis. 2017, 6 (4), 665–677. https://doi.org/10.5380/rber.v6i4.49073

Kristensen, J. B.; Börjesson, J.; Bruun, M. H.; Tjerneld, F.; Jørgensen, H. Use of active surface additives in enzymatic hydrolysis of wheat straw lignocellulose. Enzyme Microb. Technol. 2007, 40 (4), 888–895. https://doi.org/10.1016/j.enzmictec.2006.07.014

Li, Q.; He, Y.; Xian, M.; Jun, G.; Xu, X.; Yang, J.; Li, L. Improving enzymatic hydrolysis of wheat straw using ionic liquid 1-ethyl-3-methyl imidazolium diethyl phosphate pretreatment. Bioresour. Technol. 2007, 100 (14), 3570–3575. https://doi.org/10.1016/j.biortech.2009.02.040

Lu, X.; Zheng, X.; Li, X.; Zhao, J. Adsorption and mechanism of cellulase enzymes onto lignin isolated from corn stover pretreated with liquid hot water. Biotechnol. Biofuels. 2016, 9, 118. https://doi.org/10.1186/s13068-016-0531-0

Machado, B. A. S.; Reis, J. H. O.; Silva, J. B.; Cruz, L. S.; Nunes, I. L.; Pereira, F. V.; Druzian, J. I. Obtenção de nanocelulose da fibra de coco verde e incorporação em filmes biodegradáveis de amido plastificados com glicerol. Quím. Nova 2014, 37 (8), 1275–1282. https://doi.org/10.5935/0100-4042.20140220

Marques, M. N.; Cotrim, M. B.; Pires, M. A. F.; Beltrame Filho, O. Avaliação do impacto da agricultura em áreas de proteção ambiental, pertencentes à bacia hidrográfica do rio Ribeira de Iguape, São Paulo. Quím. Nova 2007, 30 (5), 1171–1178. https://doi.org/10.1590/S0100-40422007000500023

Martins, L. H. S; Rabelo, S. C.; Costa, A. C. Effects of the pretreatment method on high solids enzymatic hydrolysis and ethanol fermentation of the cellulosic fraction of sugarcane bagasse. Bioresour. Technol. 2015, 191, 312–321. https://doi.org/10.1016/j.biortech.2015.05.024

Maugeri Filho, F.; Goldbeck, R.; Manera, A. P. Produção de oligossacarídeos. In Biotecnologia Industrial-Vol. 3: Processos fermentados e enzimáticos, 2nd ed; Vol. 3, Blucher, 2019; pp 253.

Mboowa, D. A review of the traditional pulping methods and the recent improvements in the pulping processes. Biomass Conv. Bioref. 2021. https://doi.org/10.1007/s13399-020-01243-6

Meenakshisundaram, S.; Fayeulle, A.; Leonard, E.; Ceballos, C.; Pauss, A. Fiber degradation and carbohydrate production by combined biological and chemical/physicochemical pretreatment methods of lignocellulosic biomass – A review. Bioresour. Technol. 2021, 331, 125053. https://doi.org/10.1016/j.biortech.2021.125053

Mengesha, Y.; Tebeje, A.; Tilahun, B. A Review on Factors Influencing the Fermentation Process of Teff (Eragrostis teff) and Other Cereal-Based Ethiopian Injera. Int. J. Food Sci. 2022, 2022, 4419955. https://doi.org/10.1155/2022/4419955

Montagnoli, M. S.; Souza, O.; Furigo Junior, A. Produção de etanol 2G de pseudocaule de bananeira por cocultura microbiana. Blucher Chem. Eng. Proc. 2018, 1 (5),160–163. https://doi.org/10.5151/cobeq2018-PT.0049

Ogeda, T. L.; Petri, D. F. S. Hidrólise Enzimática de Biomassa. Quim. Nova. 2010, 33 (7), 1549–1558. https://doi.org/10.1590/S0100-40422010000700023

Rabemanolontsoa, H.; Saka, S. Comparative study on chemical composition of various biomass species. RSC Advances. 2013, 3 (12), 3946–3956. https://doi.org/10.1039/C3RA22958K

Rosa, S. E. S.; Garcia, J. L. F. O etanol de segunda geração: limites e oportunidades. Revista do BNDES. 2009, 32, 117–156.

Santos, F. A.; Queiróz, J. H.; Colodette, J. L.; Fernandes, S. A.; Guimarães, V. M.; Rezende, S. T. Potencial da palha de cana-de-açúcar para produção de etanol. Quím. Nova 2012, 35 (5), 1004–1010. https://doi.org/10.1590/S0100-40422012000500025

Saritpongteerak, K.; Kaewsung, J.; Charnnok, B.; Chaiprapat, S. Comparing Low-Temperature Hydrothermal Pretreatments through Convective Heating versus Microwave Heating for Napier Grass Digestion. Processes. 2020, 8 (10), 1221. https://doi.org/10.3390/pr8101221

Scapini, T.; Santos, M. S. N.; Bonatto, C.; Wancura, J. H. C.; Mulinari, J.; Camargo, A. F.; Klanovicz, N.; Zabo, G. L.; Tres, M. V.; Fongaro, G.; Treichel, H. Hydrothermal pretreatment of lignocellulosic biomass for hemicellulose recovery, Bioresource Technology 2021, 342, 126033. https://doi.org/10.1016/j.biortech.2021.126033

Silva, V. T. F.; Ruschoni, U. C. M.; Ferraz, A.; Milagres, A. M. F. Xylan, Xylooligosaccharides, and Aromatic Structures with Antioxidant Activity Released by Xylanase Treatment of Alkaline-Sulfite-Pretreated Sugarcane Bagasse. Front. Bioeng Biotechnol. 2022, 10, 940712. https://doi.org/10.3389/fbioe.2022.940712

Souza, O.; Schulz, M. A.; Fischer, G. A. A.; Wagner, T. M.; Sellin, N. Energia alternativa de biomassa: bioetanol a partir da casca e da polpa de banana. Rev. Bras. de Eng. Agric. Ambient. 2012, 16 (8), 915–921. https://doi.org/10.1590/S1415-43662012000800015

Tse, T. J.; Wiens, D. J.; Reaney, M. J. T. Production of Bioethanol—A Review of Factors Affecting Ethanol Yield. Fermentation. 2021, 7 (4), 268. https://doi.org/10.3390/fermentation7040268

Tsubaki, S.; Oono, K.; Onda, A.; Ueda, T.; Mitani, T.; Hiraoka, M. Microwave-assisted hydrolysis of biomass over activated carbon supported polyoxometalates. RSC Adv. 2017, 7 (20), 12346–12350. https://doi.org/10.1039/C6RA28778F

União Nacional do Etanol de Milho (UNEM). A Hegemonia do Etanol. 2021. http://etanoldemilho.com.br/2020/02/03/a-hegemonia-do-etanol/ (accessed 2021-06-21).

United States Environmental Protection Agency (US EPA). Inventory of U.S. Greenhouse Gas Emissions and Sinks. 2021. https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks (accessed 2021-06-20).

Wang, F.-L.; Lo, S.; Sun, Y.-X.; Han, H.-Y.; Zhang, B.-X.; Hu, B.-Z.; Gao, Y.-F.; Hu, X.-M. Ionic liquids as efficient pretreatment solvents for lignocellulosic biomass. RSC Adv. 2017, 7 (76), 47990–47998. https://doi.org/10.1039/C7RA08110C

Wei, L.; Li, K.; Ma, Y.; Hou, X. Dissolving lignocellulosic biomass in a 1-butyl-3-methylimidazolium chloride–water mixture. Ind. Crops Prod. 2012, 37 (1), 227–234. https://doi.org/10.1016/j.indcrop.2011.12.012

Yu, X.; Bao, X.; Zhou, C.; Zhang, L.; Yagoub, A. E.-G. A.; Yang, H.; Ma, H. Ultrasound-ionic liquid enhanced enzymatic and acid hydrolysis of biomass cellulose. Ultrason. Sonochem. 2018, 41, 410–418. https://doi.org/10.1016/j.ultsonch.2017.09.003

Zanivan, J.; Bonatto, C.; Scapini, T.; Dalastra, C.; Bazoti, S. F.; Alves Júnior, S. L.; Fongaro, G.; Treichel, H. Avaliação da produção de bioetanol a partir de resíduos mistos de frutas por Wickerhamomyces sp. UFFS-CE-3.1.2. Bioenergia. Res. 2022, 15 (1), 175–182. https://doi.org/10.1007/s12155-021-10273-5

Zhao, X.; Huang, C.; Lin, W.; Bian, B.; Lai, C.; Ling, Z.; Yong, Q. A structure–activity understanding of the interaction between lignin and various cellulase domains. Bioresource Technology. 2022, 351, 127042, https://doi.org/10.1016/j.biortech.2022.127042

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright (c) 2023 Eclética Química