Abstract

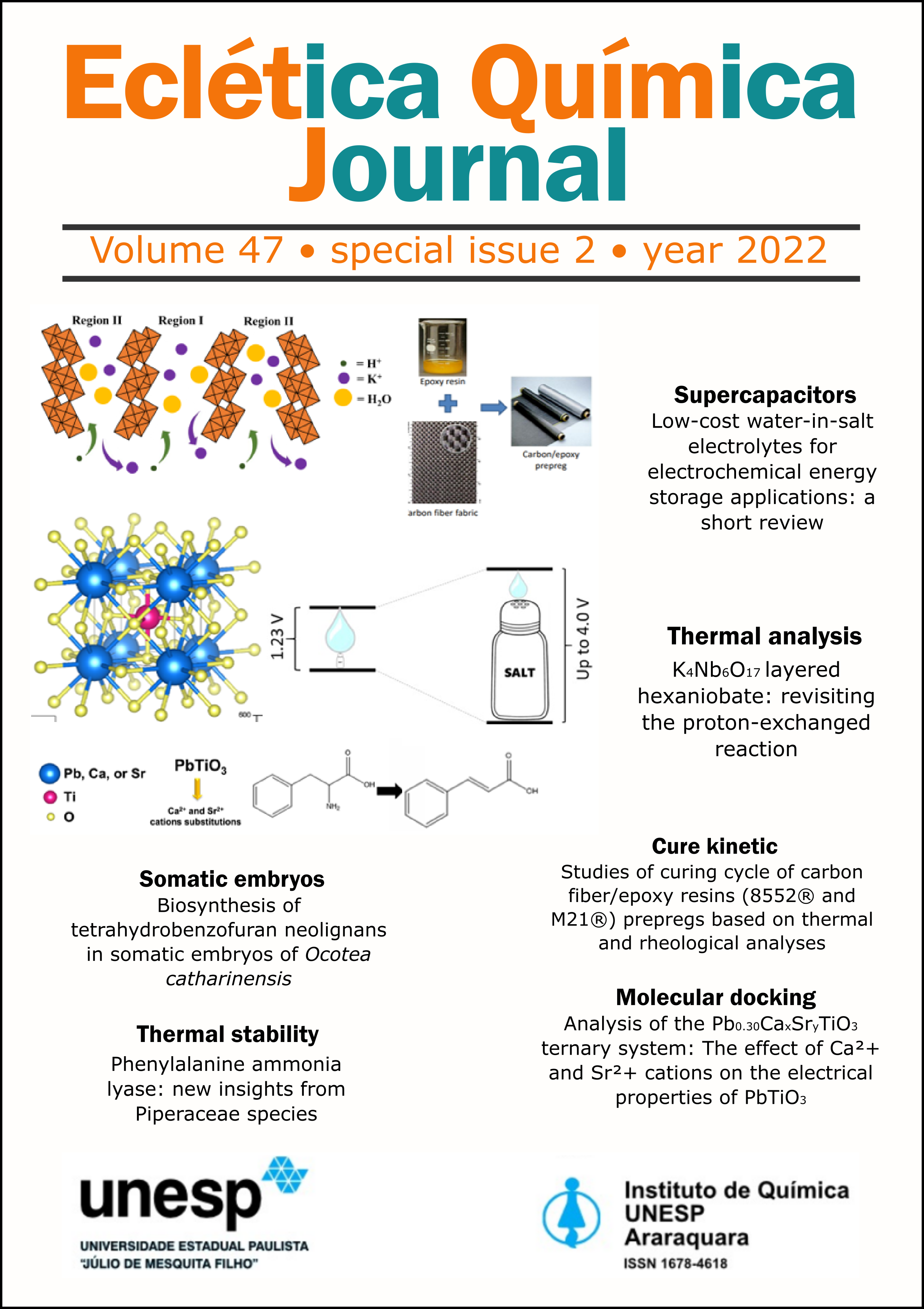

Thermal and rheological characterizations were performed on prepreg produced with two different commercial epoxy resins - M21® and 8552® – aiming to study and optimize the curing cycle of structural components used in aerospace industry. Characterizations were performed by differential scanning calorimetry (DSC), rheology and dynamic mechanical analysis techniques were assessed and the results were correlated and supported by Fourier Transform Infrared spectroscopy. Additionally, to heating rates suggested by the material supplier, DSC analysis allowed to evaluate further heating rates: 2, 5, 10, 15 and 20 °C/min. Materials presented the n fractional order kinetic of cure and have in its formulation the presence of thermoplastics, in addition to epoxy and amine. Results confirmed that the best heating rates for processing both materials are the lower ones, as they result in a better control of the reactions between chemical compounds involved and the physical changes that are part of curing process stages. Results have analytically confirmed the suggested proposal for curing cycle from supplier is the best choice for materials involved.

References

Agius, S. L.; Magniez, K. J. C.; Fox, B. L. Cure behaviour and void development within rapidly cured out-of-autoclave composites. Compos. B. Eng. 2013, 47, 230–237. https://doi.org/10.1016/j.compositesb.2012.11.020

ASTM E1356-08. Standard Test Method for Assignment of the Glass Transition Temperatures by Differential Scanning Calorimetry. ASTM International, 2014a. https://doi.org/10.1520/E1356-08R14

ASTM E968-02. Standard Practice for Heat Flow Calibration of Differential Scanning Calorimeters. ASTM International, 2014b. https://doi.org/10.1520/E0968-02R14

ASTM D7028-07e1. Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA). ASTM International, 2015. https://doi.org/10.1520/D7028-07E01

ASTM E967-18. Standard Test Method for Temperature Calibration of Differential Scanning Calorimeters and Differential Thermal Analyzers. ASTM International, 2018. https://doi.org/10.1520/E0967-18

ASTM D4473-08. Standard Test Method for Plastics: Dynamic Mechanical Properties: Cure Behavior. ASTM International, 2021. https://doi.org/10.1520/D4473-08R21

Botelho, E. C.; Scherbakoff, N.; Rezende, M. C. Porosity control in glassy carbon by rheological study of the furfuryl resin. Carbon. 2001, 39 (1), 45–52. https://doi.org/10.1016/S0008-6223(00)00080-4

Braga, C. I.; Rezende, M. C.; Costa, M. L. Methodology for DSC calibration in high heating rates. J. Aerosp. Technol. Manag. 2011, 3 (2), 179–192. https://doi.org/10.5028/jatm.2011.03021911

Costa, M. L.; Botelho, E. C.; Paiva, J. M. F. D.; Rezende, M. C. Characterization of cure of carbon/epoxy prepreg used in aerospace field. Mater. Res. 2005, 8 (3), 317–322. https://doi.org/10.1590/S1516-14392005000300016

Costa, M. L.; Rezende, M. C.; Paiva, J. M. F.; Botelho, E. C. Structural carbon/epoxy prepregs properties comparison by thermal and rheological analyses. Polym. Plast. Technol. Eng. 2006, 45 (10), 1143–1153. https://doi.org/10.1080/03602550600887251

Das, P. P.; Chaudhary, V. Tribological and dynamic mechanical analysis of bio-composites: A review. Mater. Today: Proc. 2019, 25 (4), 729–734. https://doi.org/10.1016/j.matpr.2019.08.233

Ersoy, N.; Tugutlu, M. Cure kinetics modeling and cure shrinkage behavior of a thermosetting composite. Istanbul: Bogazici University. Polym. Eng. Sci. 2010, 50 (2), 84–92. https://doi.org/10.1002/pen.21514

Friedman, H. L. Kinetics of thermal degradation of char‐forming plastics from thermogravimetry. Application to a phenolic plastic. J. Polym. Sci., polym. Symp. 1964, 6 (1), 183–195. https://doi.org/10.1002/polc.5070060121

González-Benito, J. The nature of the structural gradient in epoxy curing at a glass fiber/epoxy matrix interface using FTIR imaging. J. Colloid Interface Sci. 2003, 267 (2), 326–332. https://doi.org/10.1016/S0021-9797(03)00550-2

Hatter, C. B.; Shah, J.; Anasori, B.; Gogotsi, Y. Micromechanical response of two-dimensional transition metal carbonitride (MXene) reinforced epoxy composites. Compos. B. Eng. 2020, 182, 107603. https://doi.org/10.1016/j.compositesb.2019.107603

Hexcel Corporation. HexPly® 8552 Epoxy matrix (180°C/356°F curing matrix). 2021a. https://www.hexcel.com/user_area/content_media/raw/HexPly_8552_us_DataSheet.pdf (accessed 2021-08-11).

Hexcel Corporation. HexPly® M21 Epoxy matrix (180°C/350°F curing matrix). 2021b. https://www.hexcel.com/user_area/content_media/raw/HexPly_M21_global_DataSheet.pdf (accessed 2021-08-11).

Hubert, P.; Johnston, A.; Poursartip, A.; Nelson, K. Cure kinetics and viscosity models for Hexcel 8552 epoxy resin. In International SAMPE symposium and exhibition. SAMPE. 2019.

Liu, H.; Falzon, B. G.; Tan, W. Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Compos. B. Eng. 2018, 136, 101–118. https://doi.org/10.1016/j.compositesb.2017.10.016

Menard, K. P. Dynamic mechanical analysis: A practical introduction. CRC Press. 1999. https://doi.org/10.1201/9781420049183

Mesogitis, T.; Kratz, J.; Skordos, A. A. Heat transfer simulation of the cure of thermoplastic particle interleaf carbon fibre epoxy prepregs. J. Compos. Mater. 2018 53 (15), 2053–2064. https://doi.org/10.1177/0021998318818245

Mphahlele, K.; Ray, S. S.; Kolesnikov, A. Cure kinetics, morphology development, and rheology of a high-performance carbon-fiber-reinforced epoxy composite. Compos. B. Eng. 2019, 176, 107300. https://doi.org/10.1016/j.compositesb.2019.107300

Newcomb, B. A. Time-Temperature-Transformation (TTT) diagram of a carbon fiber epoxy prepreg. Polym. Test. 2019, 77, 105859. https://doi.org/10.1016/j.polymertesting.2019.04.006

Nixon-Pearson, O. J.; Belnoue, J. H.; Ivanov, D. S.; Potter, K. D.; Hallett, S. R. An experimental investigation of the consolidation behaviour of uncured prepregs under processing conditions. J. Compos. Mater. 2017, 51 (13), 1911–1924. https://doi.org/10.1177/0021998316665681

Oishi, S. S.; Rezende, M. C.; Origo, F. D.; Damião, A. J.; Botelho, E. C. Viscosity, pH, and moisture effect in the porosity of poly(furfuryl alcohol). J. Appl. Polym. Sci. 2013, 128 (3), 1680–1686. https://doi.org/10.1002/app.38332

Paiva, J. M.; Costa, M. L.; Rezende, M. C. Evaluation of thermal stability and glass transition temperature of different aeronautical polymeric composites. Polym. Plast. Technol. Eng. 2006, 45 (2), 157–164. https://doi.org/10.1080/03602550500373915

Paris, C.; Olivier, P. A.; Bernhart, G. Modelling of the thermokinetic behaviour and the phases transitions of a carbon/polymeric composite submitted to high heating rate ramps. Int. J. Mater. Form. 2010, 3 (1), 639–642. https://doi.org/10.1007/s12289-010-0851-8

Paris, C.; Bernhart, G.; Olivier, P. A.; Almeida, O. Influence of fast curing cycles on aeronautical prepreg M21/T700: polymerization control and mechanical properties. Mater. Tech. 2012, 100 (6–7), 611–622. https://doi.org/10.1051/mattech/2012010

Ribeiro, B.; Nohara, L. B.; Oishi, S. S.; Costa, M. L.; Botelho, E. C. Carbon nanotubes/polyamide 6.6 nanostructured composites crystallization kinetic study. J. Thermoplast. Compos. Mater. 2013, 26 (7), 893–911. https://doi.org/10.1177/0892705711430532

Sánchez-Soto, M.; Pagés, P.; Lacorte, T.; Briceño, K.; Carrasco, F. Curing FTIR study and mechanical characterization of glass bead filled trifunctional epoxy composites. Compos. Sci. Technol. 2007, 67 (9), 1974–1985. https://doi.org/10.1016/j.compscitech.2006.10.006

Silverstein, M.; Webster, F. X.; Kiemle, D. J. Spectrometric identification of organik compounds. John Wiley & sons. 2000.

Ștefanov, T.; Ryan, B.; Ivanković, A.; Murphy, N. Dynamic mechanical analysis of carbon black filled, elastomer-toughened ethyl cyanoacrylate adhesive bulk films. Int. J. Adhes. Adhes. 2020, 101, 102630. https://doi.org/10.1016/j.ijadhadh.2020.102630

Ueda, M.; Yokoo, T.; Nakamura, T. Synthesis of poly (ether‐sulfone‐amide)s by palladium‐catalyzed polycondensation of aromatic dibromides containing ether sulfone structure, aromatic diamines, and carbon monoxide. J. Polym. Sci., Part A: Polym. Chem. 1994, 32 (15), 2989–2995. https://doi.org/10.1002/pat.4328

Urban, V. M.; Machado, A. L.; Vergani, C. E.; Jorge, E. G.; Santos, L. P.; Leite, E. R.; Canevarolo, S. V. Degree of conversion and molecular weight of one denture base and three reline submitted to post–polymerization treatments. Mat. Res. 2007, 10 (2), 191–197. https://doi.org/10.1590/S1516-14392007000200016

Vyazovkin, S.; Burnham, A. K.; Criado, J. M.; Pérez-Maqueda, L. A.; Popescu, C.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for performing kineticcomputations on thermal analysis data. Thermochim. Acta. 2011, 520 (1–2), 1–19. https://doi.org/10.1016/j.tca.2011.03.034

Vyazovkin, S.; Chrissafis, K.; Di Lorenzo, M. L.; Koga, N.; Pijolat, M.; Roduitf, B.; Sbirrazzuoli, N.; Suñol, J. J. ICTAC Kinetics Committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim. Acta. 2014, 590, 1–23. https://doi.org/10.1016/j.tca.2014.05.036

Wang, Y.; Chea, M. K.; Belnoue, J. P.-H.; Kratz, J.; Ivanov, D. S.; Hallett, S. R. Experimental characterisation of the in-plane shear behaviour of UD thermoset prepregs under processing conditions. Compos. - A: Appl. Sci. Manuf. 2020, 133, 105865. https://doi.org/10.1016/j.compositesa.2020.105865

Wetton, R. E.; Marsh, R. D. L.; Van-de-Velde, J. G. Theory and application of dynamic mechanical thermal analysis. Thermochim. Acta. 1991, 175 (1), 1–11. https://doi.org/10.1016/0040-6031(91)80240-J

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright (c) 2022 Eclética Química Journal